CONVENTIONAL SAFETY DELIVERS LIMITED RESULTS

Are you tired of safety programs and initiatives that cost money and don’t deliver sustainable results or return on investment? Let’s explore why conventional safety practices often fall short and how innovative strategies will revolutionize your organization’s safety culture and performance.

CONVENTIONAL SAFETY

President Richard Nixon signed the Occupational Safety and Health Act on December 29, 1970. This began the birth of the Occupational Safety and Health Administration (OSHA) on April 28th, 1971. Safety Management Systems were developed and implemented in the 1980’s. The results, US worker deaths are down on average from 38 worker deaths a day in 1970. To 15. Worker deaths a day in 2023. While we can take a moment to recognize progress, let’s not spend too much time doing so. I am sure you will agree that 15 families/day not getting to hug their mom, dad, daughter, son, sister, or brother at the end of their work shift is horrifying.

Safety traditionally is highly focused on elements and often engages in a command-and-control approach. Think of Command & Control as telling the employee everything they should do, rather than allowing the employee to make decisions on their own.

As you read the above words, how are you feeling? De-motivated, defensive? How does your safety culture make people feel? Many organizations title their Safety professional, Safety Officer. How does that make an employee feel? When was the last time you were pulled over by a police officer and given positive feedback?

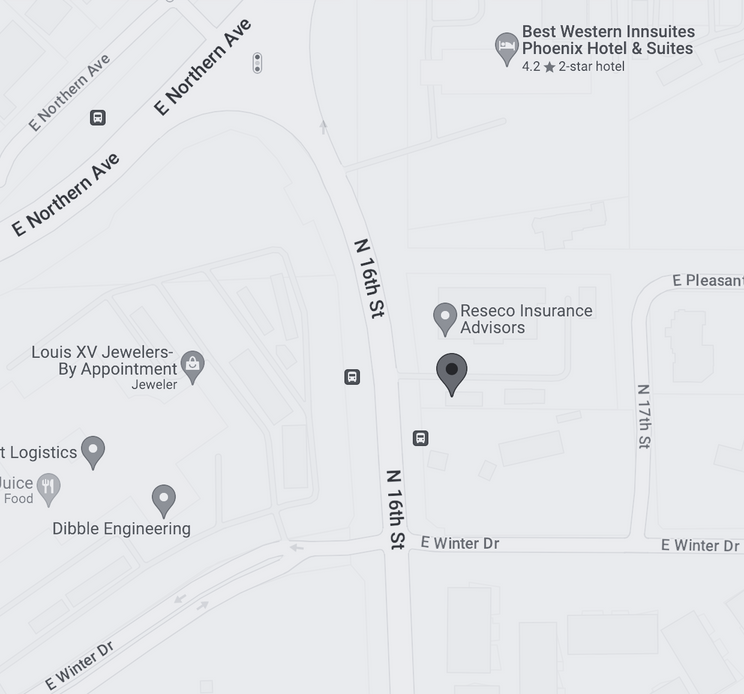

Some very common safety metrics include OSHA recordable injuries, OSHA recordable case rate, DART rate., experience modification factor (E-Mod), frequency rate, severity rate, incident reporting, lag time, near misses, and so many more. These elements all have one thing in common, they are lagging indicators and are the equivalent of looking in the rearview mirror of your vehicle. E-Mod uses injury claims from 4 years ago.

So, I ask, how often are you looking in the rearview mirror when you drive your vehicle? The National Safety Council says you should quickly check your rearview mirror every 5 to 8 seconds. Using 6 seconds would equate to 10% of the time, which means we should be looking through the windshield 90% of the time.

What percentage of the time is spent focused on rearview mirror issues and metrics? I have asked hundreds of safety professionals what percentage of the time they spend being proactive versus reactive. The answer I get ranges between 10- 25% proactive, or 75 – 90% reactive. It is not possible to intentionally transform your safety culture to a high-level performing culture spending this little time being strategic and proactive.

A study recently performed by SHRM showed that 70% of American workers are disengaged. Disengagement means not focused on the task at hand. When it comes to safety, this is truly scary. On a scale of 1 – 10, 10 being Amazing, what is your rating for the employee engagement in your safety culture?

Jim Rohn put it this way…

If you keep doing what you’ve always done, you’ll keep getting what you’ve always got.”

- Jim Rohn

A MUCH BETTER WAY!

I have seen safety manuals of more than 300 pages. How much can your leaders and employees recall? So how do we move in a better direction? Bring focus to the most critical work behaviors and actions. Focus on the actions we want our people to take. That if taken, will send the person home healthy to the ones they love. When not performed, it means the person is risking life-ending or altering results.

You have subject matter experts at all levels within your company who know what is most critical. Educating all employees about what they need to do to work safely versus not violating rules or regulations is a huge step in the right direction. Then building supporting activities for supervisors and managers to perform consistently will demonstrate commitment and care. Once the entire team is integrated, you will be rowing the boat in rhythm, with the intention to a clear destination.

The above steps are the beginning of the ingredient towards creating a Culture of Accountability. A culture where at some point, co-workers plan together, watch out for each other, encourage each other, and make sure nobody would allow someone to risk their life for a paycheck. A culture of very high engagement.

A National, Heavy-Civil Construction firm that has grown revenue by over 7x and employees by 5x began its Culture of Accountability journey in 2016. Their Design Team began focusing on 11 specific behaviors to form strong, safe work habits. The result:

Next Week, We Will Explore: How to Create Accountability the right way.

We will continue to reveal the key ingredients of our proven process SHIELD™. These ingredients have transformed safety from a compliance requirement into a shared responsibility that resonates throughout your organization. You will:

1. Discover the limitations of developing accountability, top down.

2. Learn a unique method that creates 95% or higher employee engagement

3. Explore real-world examples of companies that have successfully embraced new safety paradigms for outstanding results.

Get access to in-depth insights, expert tips, and the latest trends in workplace safety directly to your inbox.

Don’t leave your safety program to chance. Ensure it’s as strong, effective, and proactive as it can be with our expert guidance and resources.

LET‘S

TALK!

HEAD OFFICE